Electrical panel maintenance is a systematic process ensuring the reliability and safety of electrical systems․ It involves regular inspection‚ testing‚ and servicing of electrical panels to prevent faults and ensure optimal performance․

1․1 Importance of Regular Maintenance

Regular electrical panel maintenance is crucial for ensuring the reliability‚ safety‚ and efficiency of electrical systems․ It helps prevent unexpected equipment failures‚ reduces the risk of electrical fires‚ and minimizes downtime․ By identifying potential issues early‚ maintenance extends the lifespan of electrical components and ensures compliance with safety standards․ Consistent upkeep also supports operational continuity‚ especially in industrial and commercial settings where electrical systems are critical․ Additionally‚ regular maintenance reduces long-term costs by avoiding costly repairs and ensuring optimal system performance․ It is a proactive approach to safeguarding lives‚ property‚ and business operations from electrical hazards․

1․2 Overview of Electrical Panel Maintenance Protocols

Electrical panel maintenance protocols are structured procedures designed to ensure the safe and efficient upkeep of electrical systems․ These protocols typically include visual inspections‚ testing of components‚ and replacement of worn or damaged parts․ They also involve documentation of findings and maintenance activities for future reference․ The protocols are often tailored to the specific requirements of the electrical panel and the facility it serves‚ ensuring compliance with industry standards and safety regulations․ By following these protocols‚ technicians can identify and address potential issues before they escalate‚ thereby maintaining system reliability and performance․ Regular adherence to these protocols is essential for preventing electrical hazards and ensuring uninterrupted power supply․

Safety Precautions for Electrical Panel Maintenance

Safety precautions are critical to prevent electrical hazards and ensure technician safety․ Always use PPE‚ follow lockout/tagout procedures‚ and de-energize the panel before maintenance begins․

2․1 Personal Protective Equipment (PPE) Requirements

Personal Protective Equipment (PPE) is essential for safeguarding technicians during electrical panel maintenance․ Required PPE includes high-voltage-rated gloves‚ safety glasses with side shields‚ a full-face shield‚ and arc-rated clothing․ These items protect against electrical arcs‚ flashes‚ and flying debris․ Additionally‚ insulated tools rated for the system voltage should be used to prevent shock․ Proper footwear and non-conductive headgear may also be necessary‚ depending on the work environment․ Ensuring all PPE meets industry standards‚ such as those set by ASTM or NFPA‚ is crucial for compliance and safety․ Regular inspection of PPE for wear or damage is also recommended to maintain its protective capabilities․

2․2 Lockout/Tagout Procedures

Lockout/Tagout (LOTO) procedures are critical for ensuring electrical panel safety during maintenance; These steps involve disconnecting power sources and securing them with locks and tags to prevent accidental re-energization․ Start by identifying all power sources connected to the panel and isolating them․ Apply approved locks and tags to circuit breakers or disconnects‚ clearly indicating that work is in progress․ Verify deactivation of all voltages using test equipment․ Ensure stored energy‚ such as capacitors‚ is safely discharged․ Only authorized personnel should remove locks or tags․ Compliance with OSHA and NFPA standards is mandatory․ Proper LOTO ensures technician safety and prevents electrical hazards‚ making it a cornerstone of electrical panel maintenance protocols․

Step-by-Step Electrical Panel Maintenance Protocol

A structured approach to maintaining electrical panels involves visual inspections‚ testing connections‚ replacing damaged components‚ and documenting findings to ensure safety and efficiency‚ following established guidelines․

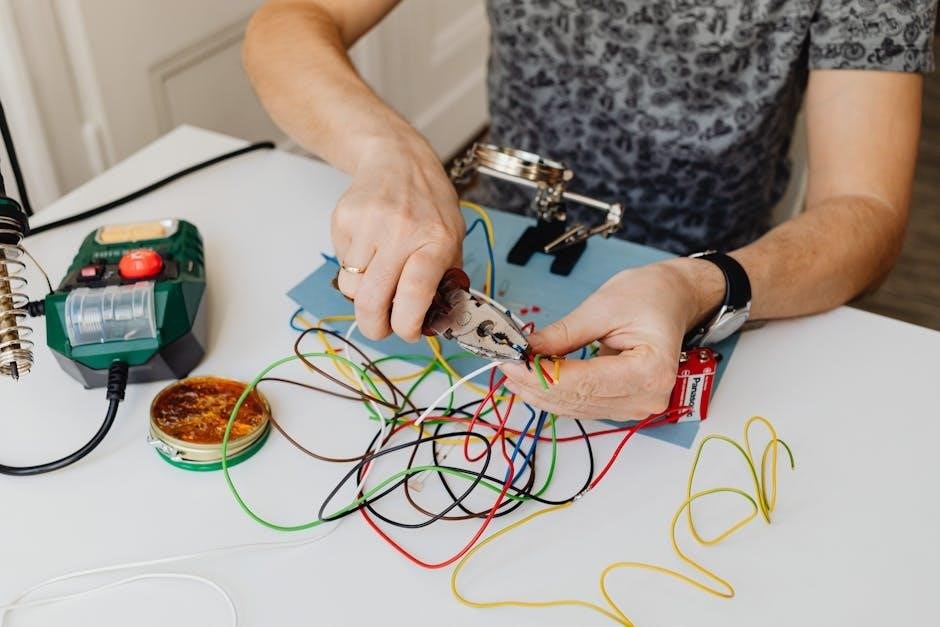

3․1 Visual Inspection of the Panel and Components

The visual inspection is the first step in electrical panel maintenance․ It involves examining the panel’s exterior and interior for signs of damage‚ wear‚ or overheating․ Check for loose connections‚ rust‚ corrosion‚ or discoloration on components like circuit breakers‚ fuses‚ and busbars․ Look for cracks in wiring insulation or signs of arcing․ Ensure all labels are clear and up-to-date․ Verify that the panel is properly sealed to prevent dust or moisture ingress․ This step helps identify potential issues before they escalate‚ ensuring safety and system reliability․ Document any findings for further investigation or corrective action during the maintenance process․

3․2 Testing and Verification of Electrical Connections

Testing and verification of electrical connections are critical to ensure the integrity and safety of the panel․ Use a multimeter to measure voltage‚ resistance‚ and continuity across connections‚ busbars‚ and components․ Check for any open circuits‚ short circuits‚ or ground faults․ Verify that all electrical connections are tight and meet the manufacturer’s torque specifications․ Inspect the busbars for proper alignment and cleanliness․ Test circuit breakers and fuses to ensure they function correctly under load․ Use thermal imaging to detect abnormal heat signatures‚ which may indicate loose or faulty connections․ Document all test results and address any discrepancies immediately to prevent potential failures․ This step ensures the electrical panel operates efficiently and safely‚ minimizing the risk of downtime or hazards․

3․3 Replacement of Damaged or Worn-Out Parts

Replacing damaged or worn-out parts is essential to maintain the electrical panel’s performance and safety․ Identify faulty components such as fuses‚ circuit breakers‚ relays‚ or contactors through visual inspection and testing․ Use a multimeter to verify the condition of these parts before replacement․ Always disconnect power to the panel before starting any replacement work․ Replace damaged components with genuine‚ OEM-approved parts to ensure compatibility and reliability․ Tighten all connections to the specified torque to prevent loose connections․ After replacement‚ test the panel under load to ensure proper functioning․ Document the replaced parts and the date of replacement for future reference․ This step ensures the panel operates safely and efficiently‚ preventing potential failures and hazards․

Maintaining Records of Electrical Panel Inspections and Maintenance

Maintaining detailed records of inspections and maintenance ensures compliance‚ safety‚ and future planning․ Use standardized templates to document findings‚ actions taken‚ and schedules for tracking and verification purposes․

4․1 Creating Detailed Inspection Reports

Creating detailed inspection reports is crucial for documenting the condition of electrical panels and ensuring accountability․ These reports should include a comprehensive checklist of components inspected‚ such as circuit breakers‚ fuses‚ and wiring․ Measurements from testing procedures‚ like voltage levels and resistance‚ should also be recorded․ Any discrepancies or potential hazards must be noted‚ along with corrective actions taken․ Reports should be standardized to facilitate easy review and compliance with safety regulations․ Proper documentation ensures that maintenance activities are tracked and provides a clear record for future reference․ This helps in identifying recurring issues and planning preventive maintenance effectively‚ ultimately enhancing system reliability and safety․

4․2 Updating Maintenance Logs for Future Reference

Updating maintenance logs is essential for maintaining a comprehensive history of electrical panel servicing․ These logs should include dates of inspections‚ details of repairs‚ and any components replaced․ By documenting all maintenance activities‚ logs provide valuable insights into the system’s condition over time․ This information aids in identifying patterns of wear or recurring issues‚ enabling proactive measures․ Logs also serve as legal and compliance documentation‚ ensuring adherence to safety standards․ Regular updates ensure continuity and provide a clear audit trail for future technicians․ Accurate and timely log updates are vital for maintaining system reliability and supporting long-term asset management strategies․ They ensure that all maintenance efforts are recorded and accessible for future reference․

Best Practices for Electrical Panel Maintenance

Adhering to best practices ensures electrical panels operate safely and efficiently․ Regular inspections‚ proper labeling‚ and using genuine parts are crucial for maintaining system integrity and reliability․

5․1 Scheduled Maintenance Frequency and Checklists

Scheduled maintenance frequency varies based on usage and environment․ High-use panels may require quarterly checks‚ while others need annual inspections․ Checklists should include visual inspections‚ connection testing‚ and component replacements․ Using standardized templates ensures consistency․ Logs help track maintenance history‚ aiding in future planning․ Proper documentation is essential for compliance and accountability; Regular reviews of maintenance schedules ensure they remain effective․ Adhering to these practices minimizes downtime and enhances safety․

5․2 Labeling and Documentation Standards

Accurate labeling of electrical panels is critical for safety and efficiency․ Labels should clearly indicate circuit breakers‚ fuses‚ and their corresponding loads․ Documentation must include detailed maintenance records‚ inspection reports‚ and component replacement logs․ Standardized templates ensure consistency and compliance with regulations․ Proper labeling reduces risks during emergencies and maintenance tasks․ Regular updates to documentation are essential to reflect system changes․ Adherence to these standards enhances operational clarity and accountability‚ ensuring that all personnel can access and understand vital information quickly․ This practice also supports future maintenance planning and troubleshooting efforts effectively․

king of the underworld rj kane pdf

king of the underworld rj kane pdf  mark cousins the story of film pdf

mark cousins the story of film pdf  algebra workbook pdf

algebra workbook pdf  the other end of the leash pdf

the other end of the leash pdf  schedule pipe chart pdf

schedule pipe chart pdf  l tec 225 mig welder parts manual pdf

l tec 225 mig welder parts manual pdf  merlin home transmitter manual

merlin home transmitter manual  contrat de sous-location québec pdf

contrat de sous-location québec pdf